Toyota trucks have been sought after by people all over the world due to the incredible longevity that many of them have attained, while also under extreme circumstances. One of the best engines was the little 22r, which went into service in 1982 and lasted until the multi-valve tacoma engines replaced it completely in 1996. As great and reliable as the 22r was, it was severely dated as far as emissions, power, and gas mileage.

When the Tacoma came out, three engines were available- a 2.4liter 4cyl found only in the 2-wheel drive trucks, a 2.7liter 4cylinder found in the 4wheel drive, Pre-Runner, and the T100 (while it lasted) and a 3.4 liter V6. The 2.7 was basically a larger displacement version of the smaller 2.4 and as such the rotating mass of the crank, connecting rods, and pistons was higher. With the added weight came the problem of engine vibration.

Since each cylinder of a 4cyl engine is responsible for 180 degrees of a 4 stroke engine’s 720° cycle they are prone to be less smooth than that of engines with more cylinders. That is why a V8 (720°/8 =90° ) can have a misfire, and you might not even notice. Toyota’s solution to the extra vibration was to have two counter-rotating balance shafts to cancel out the buzz or vibration.

Which brings us to the purpose of this article: These balance shafts will fail eventually, destroying the engine in the process. What causes the failure is usually a combination of factors, namely high mileage, previous engine repair, overheating, lack of oil, and coolant-contaminated engine oil.

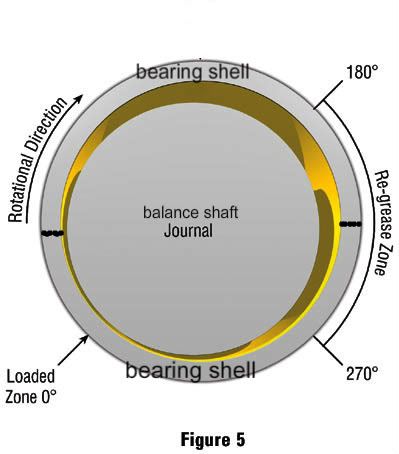

Engine bearings are not bearings with rollers or ball bearings, instead they rely on a very thin film of oil in-between the 2 metal surfaces. When a vehicle is first started, there is not much of a film until the oil pump can supply oil to the entire engine which takes a few seconds. Virtually all bearing wear happens during start-up since, theoretically at least, the two metal surfaces never touch since they “float” on a film of oil (for a great article on how amazing this is click here). What kills the bearings fastest is mentioned above.

Lack of oil, coolant contamination of the oil, and engine repair are probably the most common causes of bearing failure on the balance shafts in this motor. When coolant mixes with oil it will do very bad things to the bearing surface. It will thin out the oil and allow metal-to-metal contact, and it will corrode or etch the surface of the bearing. Added to this scenario is the over-heating that usually happens once the headgasket has failed and let all the coolant out of the cooling system. Unfortunately the balance shafts on the Tacoma 2.7 do not get lubricated all that great anyway, which is why they are the first to seize bearings. These are immediate effects but there is also the after effects of doing a headgasket repair.

Endeavoring a headgasket repair on the 3rz-fe requires that the vehicle owner is informed of the risk of engine destruction if the cylinder block is left un-attended to. Besides the risk of coolant contamination, there is also the risk of foreign obstacle obstruction to the oil passage-ways from headgasket material being cleaned off of the engine block during the repair, and dropping into the oil pan. Added to the list of bearing killers is the use of abrasive sanding discs to clean the engine block surface. These discs use a woven mesh that contains aluminum oxide, and work very well to remove gasket material, but then they shed aluminum oxide into the engine which acts like sandpaper on the engine bearings. We do not use these discs, instead we use a hardened-rubber bristle disc.

Unfortunately, we have come to the conclusion (the hard way) that the only way to repair the 3rz-fe properly after a blown headgasket (short of a complete rebuild), is to remove the balance shafts and replace the rod and main bearings. LC Engineering makes a great kit to remove the balance shafts permanently, but the lack of balance shafts does tend to make the truck a little buzzy at certain engine loads and rpm combinations. The vibration that you would experience would make it feel like the truck had really old and hard engine mounts, but it does liven the engine up and let it spin easier to higher RPMs.